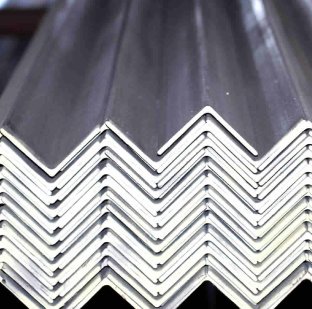

MS Angle

Angle refers to Mild Steel (MS) angle bars or steel, which are structural steel sections that have an "L" shape, with two perpendicular legs. The angle steel is made from mild steel, which is a low-carbon steel that is commonly used in construction and manufacturing due to its strength, ductility, and affordability.

Applications Uses

- Construction

- Structural Engineering

- Furniture

- Industrial Applications

| Type | MS Angle |

|---|---|

| Grade | MS |

| Thickness | 3 mm to 20 mm depending on the required strength |

| Length | 6 meters |

| Dimensions | small angles (20x20 mm) to larger sections (up to 200x200 mm or more) |

- Steel Melting: The process starts with the production of mild steel in a steel mill, typically from scrap metal or iron ore.

- Billet or Bloom Forming: The molten steel from the furnace is cast into billets or blooms, which are large, rectangular pieces of steel.

- Hot Rolling: The solidified billets or blooms are heated to high temperatures (around 1000°C or higher) to make them malleable for rolling.

- Cooling: Once the angle steel has been shaped, it is cooled using either air cooling or water cooling (depending on the mill's setup). Controlled cooling is critical to ensure the steel’s properties (such as strength and hardness) meet the required standards.

- Straightening: After cooling, the steel angle bars may become slightly warped or bent due to the uneven cooling process. These bars go through a straightening machine, which applies pressure to straighten the angle bars to ensure they have a uniform shape.

- Cutting to Length: Once the MS angle steel has been formed and straightened, it is cut into standard lengths (usually 6 meters or custom lengths as per client requirements).

- Surface Treatment: Depending on the final application, surface treatments may be applied to the MS angle steel to improve corrosion resistance or enhance appearance

- Packaging and Shipping Once the MS angle steel has passed the quality control checks, it is packaged for transportation.

- Cost-Effective: MS angle steel is less expensive compared to higher-grade alloy steels.

- Ease of Fabrication: It is easy to cut, weld, and drill, making it suitable for a wide range of applications.

- Strength and Durability: It provides a good balance of strength, flexibility, and durability, which makes it suitable for both indoor and outdoor use.